Sheet metal

Sheet metal

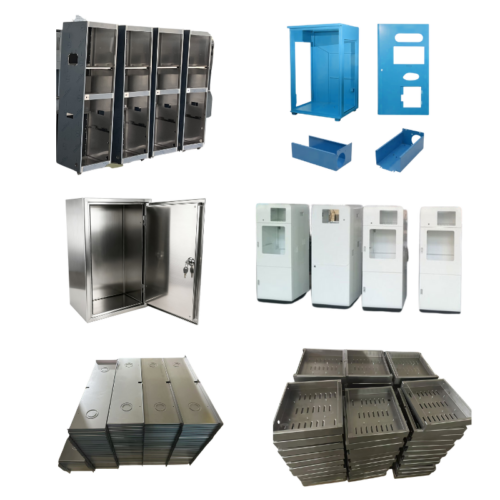

One-stop overall solution for sheet metal manufacturing. Since 2011

| Item | Specification |

|---|---|

| Product Type | Custom sheet metal enclosures, chassis, panels, brackets, cabinets, kiosks |

| Material | Cold Rolled Steel (SPCC), Galvanized Steel (SECC/SGCC), Stainless Steel 304/316/201, Aluminum 5052/6061, Copper |

| Material Thickness | 0.5 mm – 12 mm (commonly 1.0 / 1.2 / 1.5 / 2.0 / 3.0 mm) |

| Max Part Size | 4000 × 2000 mm (larger sizes by welding) |

| Manufacturing Process | Laser Cutting, CNC Punching, CNC Bending, Stamping, MIG/TIG Welding, Riveting, Assembly |

| Tolerance | ±0.10 mm – ±0.30 mm (depending on thickness and process) |

| Bending Angle | 0° – 180° |

| Surface Treatment | Powder Coating, Liquid Painting, Zinc Plating, Nickel Plating, Anodizing, Silk-Screen Printing, Laser Marking, Brushing, Polishing, Electrophoresis |

| Powder Coating Thickness | 60–120 μm (RAL & Pantone colors available) |

| Protection Level (optional) | IP54, IP65, IP66 (with gasket and sealed doors) |

| Welding Type | MIG, TIG, Spot Welding, Stud Welding |

| Assembly | PEM inserts, hinges, locks, fans, cable glands, touch screens pre-installed |

| Quality Standard | ISO 9001:2015, ISO 3834 welding certified |

| Inspection | First article inspection, 100% dimension check, leak test (if required) |

| File Formats | DXF, DWG, STEP, IGS, PDF, 3D (SolidWorks, Pro/E, UG) |

| Lead Time | Samples: 5-12 days Mass production: 15-30 days |

| MOQ | 1 piece (prototype & low-volume welcome) |

| Packaging | Foam + carton + wooden pallet (export standard) |

| Applications | Vending machines, EV chargers, medical equipment, telecom cabinets, industrial automation, kiosks, server racks |